General

This filter system is a dust separator and ideal for sucking up dust, wood chips, grit etc. in the (home) workshop or, for example, at home during a renovation. The system works as a pre-separator, filtering up to 99% of the dust which therefore does not end up in the vacuum cleaner.

This system is made from very stong ABS and HDPE and is therefor ideal in situations where the system must be able to take a beating. For example on construction sites. Also, the system can be used under humid conditions without worrying about rust. Ideal for working outside or in workshops with high humidity and no heating.

Result:

- Replace far fewer vacuum cleaner bags because almost all the dust ends up in the dustbin;

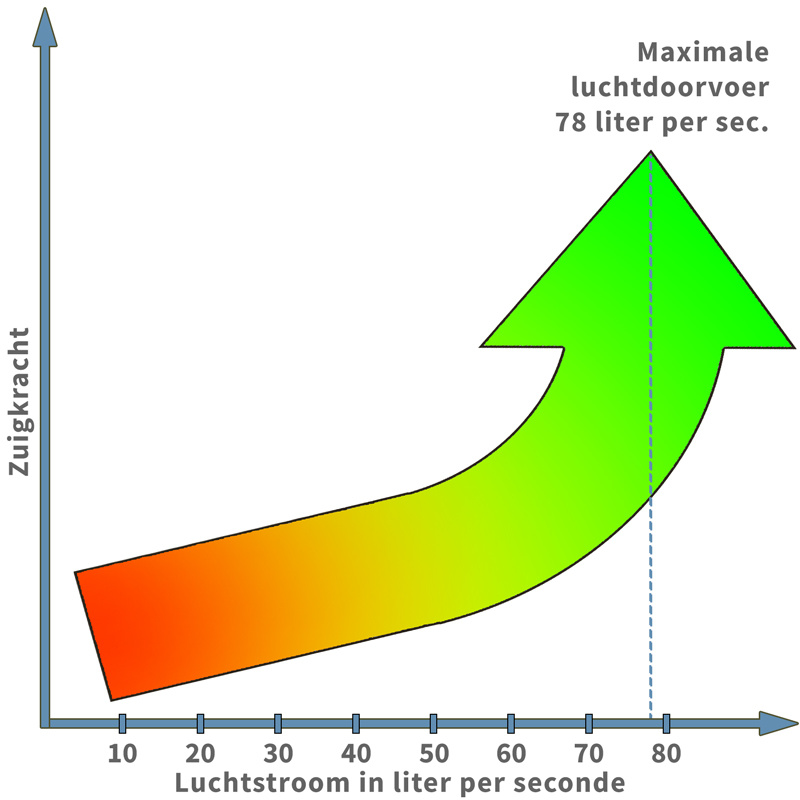

- Continuous maximum suction power because the vacuum cleaner bag hardly fills up;

- Work longer with the use of a larger dustbin in comparison with a vacuum cleaner bag;

- Longer lifespan of the vacuum cleaner due to less wear and tear on the engine.

Almost all vacuum cleaners can be connected to the filter system: standard household vacuum cleaners, (professional) shop vacuums, and extraction systems.

If you have any questions, most answers can be found on our Frequently Asked Questions page. If your question is not listed, we are happy to assist you further. Please contact us through our contact page.

Autumn sale

Free shipping from €140. Valid within the Netherlands, Belgium, and Germany.

Filter combination 3-60P consists of cyclone filter model 3 and a 60 liter dustbin (HDPE). The rubber gasket between the base of the cyclone filter and the lid of the dustbin ensures an airtight connection. Filter systems without a rubber gasket run the risk of leaking air through cracks between the base of the filter and the lid.

The dustbin has a clamping lid and is airtight due to a rubber seal in the lid. The two handles make moving the filter system easy, even when the dustbin is full.

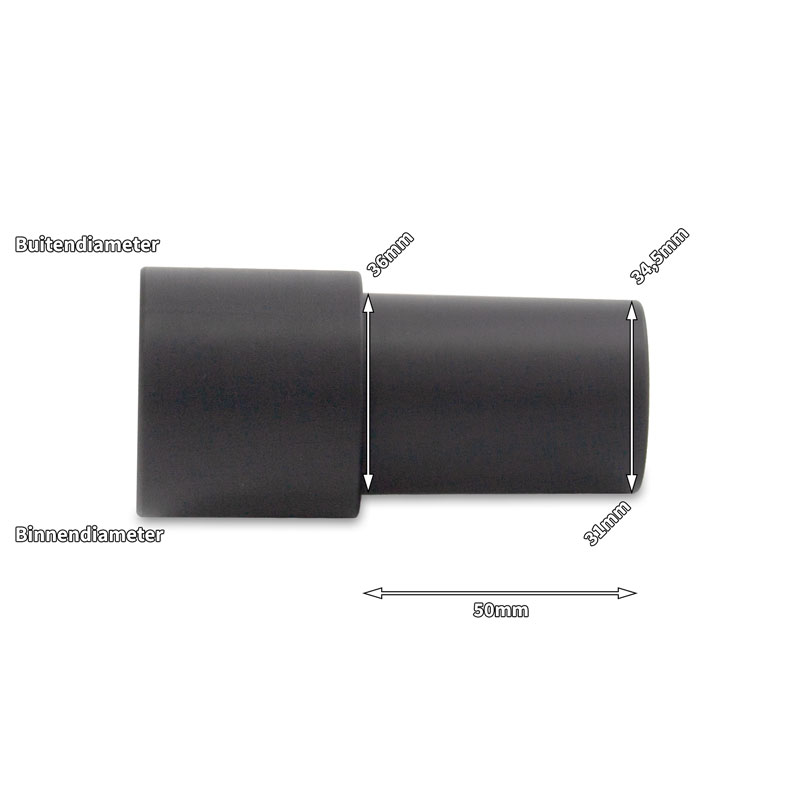

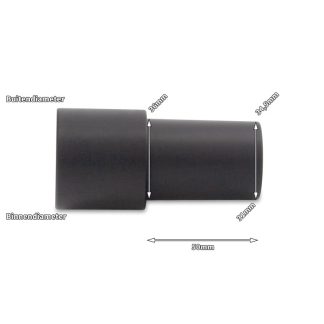

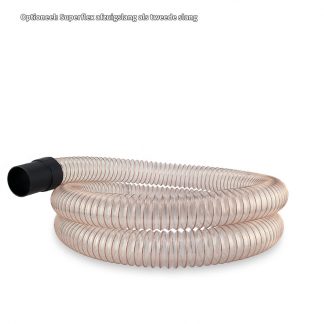

The included 2,5 meter standard hose (inner diameter 32mm) ensures a large range so you do not have to move the system every time.

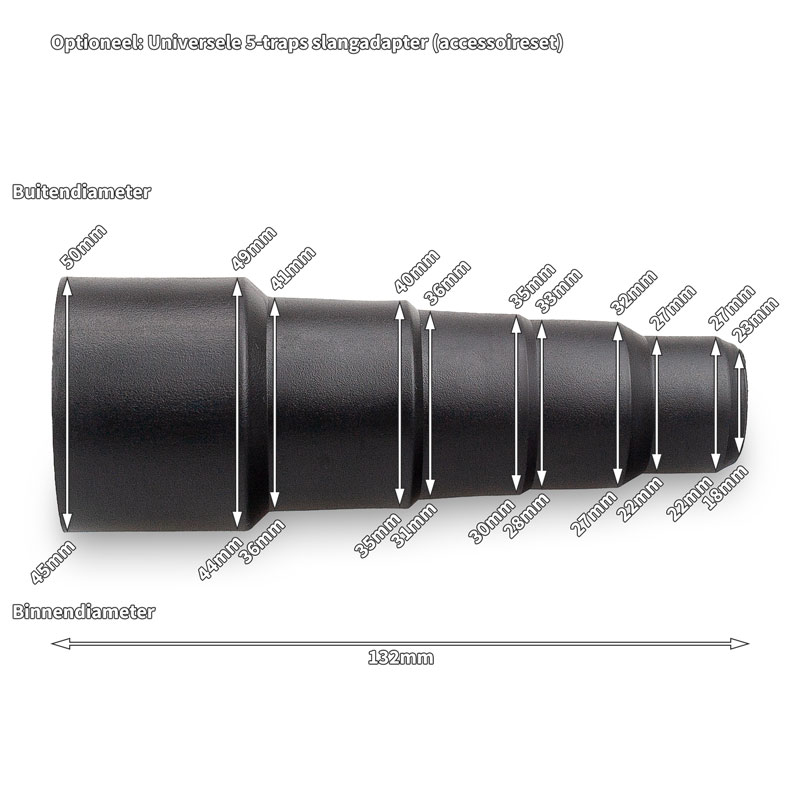

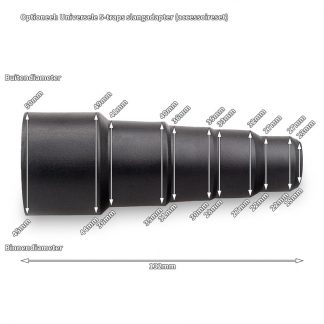

Does the 35mm nozzle of the hose not fit onto the dust ports of your machines? Then there are different types of hose adapters that can be ordered seperately. The universal 5-stage hose adapter can be ordered above as a discount set.

This set is made of high-strength ABS and HDPE, making it safe to store the system in damp, unheated workshops and sheds without the risk of rusting.

Keep using your own hose:

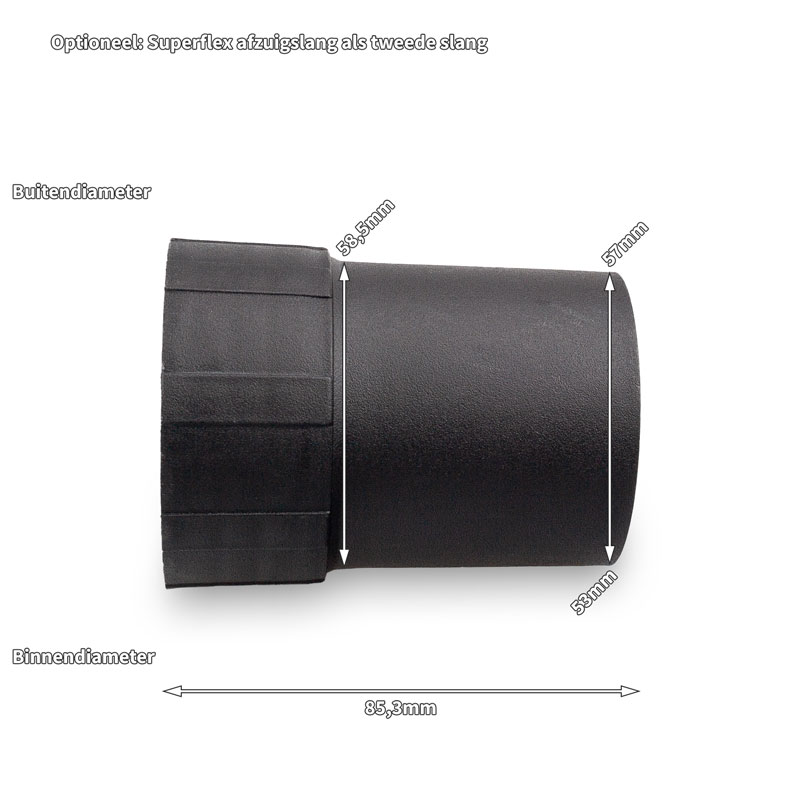

If you want to keep using your own hose on your machines, then order a filter combination (filter + dustbin) in combination with the Universal Coupling Hose. The Universal Coupling Hose connects to your vacuum cleaner and the top inlet of the filter. The coupling hose includes all parts that allow you to connect your own hose to the side inlet of the filter. The Universal Coupling Hose is suitable for many vacuum cleaners from Festool, Bosch, Makita and other brands. On the page of the Universal Coupling Hose you can find more information with which you can check whether the coupling hose also fits your vacuum cleaner.

Anti-crush pressure valve:

The filter system has an anti-crush pressure valve that is designed by us to ensure that the vacuum pressure in the dustbin does not become too high. This prevents the dustbin from collapsing due to excessive vacuum pressure. Not only professional shop vacuums, but also normal household vacuum cleaners can often generate too much vacuum pressure. Without an anti-crush pressure valve, most plastic dustbins (and even weak metal ones) will collapse when the vacuum inside the dustbin gets too high, for example when dust is being sucked up through small dust ports.

Operation:

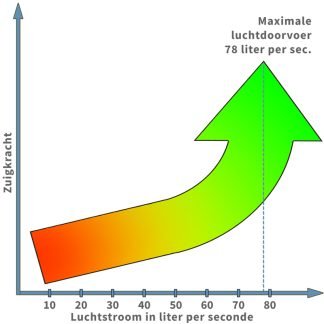

For a cyclone filter system to work properly, the anti-crush pressure valve must remain closed during normal use, otherwise dust will still end up in the vacuum cleaner. A valve that opens continuously is a sign that A. the spring resistance isn’t set correctly or B. the negative pressure is too high (for example, because dust is being sucked through a dust port that is too small). In those cases, a number of things can be done:

- Tighten the adjustment nut to increase the spring resistance. Turn the adjustment nut with a maximum of two rotations each time and then test the system. This prevents the pressure valve from being adjusted too tightly causing the valve not to open in a timely manner and thereby crushing the dustbin. For our blue dustbins the adjustment nut should be set slightly below the center of the threaded portion of the bolt.

- Lower the suctions power of the vacuum cleaner. Not too low, because there must be a basic vacuum pressure in the dustbin for proper operation.

- Use a nozzle with variable air inlet, for example our Pro-X nozzle. The nozzle can admit air from the outside by means of a slide, which reduces the vacuum pressure.

- Use a shorter hose on the side inlet of the filter. A hose creates air resistance: the longer the hose, the greater the air resistance. Greater air resistance creates greater a vacuum pressure.

- Use a hose with a larger inner diameter and a larger nozzle. As a result, more air can flow through the system which reduces the vacuum pressure.

- Reduce the number of bends in the hose that is attached to the side inlet of the filter. Every bend creates air resistance and thereby a greater vacuum pressure.

Please note: do you want to use the system on machines whose dust port has an inner diameter smaller than 30mm and do you not have a vacuum cleaner with adjustable suction power? Then we recommend using a nozzle with variable air inlet, for example our Pro-X nozzle. Smaller dust ports will cause excessive vacuum pressure, causing the valve to open continuously.

To be used with dust extraction:

- Sander;

- Table saw;

- Sand blasting machine;

- Router;

- Mitre saw;

- Wall and floor grinder;

- CNC router;

- Vacuuming shop floors;

- And many other applications.

Specifications:

- Filters up to 99%;

- Minimum air flow: 1670 liter per minute (100m3/h);

- Maximum air flow: 4667 liter per minute (280m3/h);

- Inlet and outlet inner diameter: 50mm;

- Inlet and outlet outer diameter: 56mm;

- Height: 905mm;

- Width: 400mm.

Content:

- Cyclone filter model 3;

- 60 liter dustbin (HDPE);

- Rubber gasket;

- Anti-crush pressure valve;

- Standard vacuum hose with 35mm nozzle, and connector;

- 2 x 50mm connector: outer diameter 50mm | inner diameter 46mm;

- 2 x hose clamp: range 40mm to 64mm;

- Fasteners.

- Optional: Pro-X vacuum nozzle for €13,95 instead of €19,95;

- Optional: Accessory kit for €13,95 instead of €19,95;

- Optional: Hose hanger for €8,95 instead of €9,95;

- Optional: Universal 5-stage hose adapter for €6,95 instead of €9,95 (with increasing discount).

Important:

- Do you want to use the system on machines whose dust port has an inner diameter smaller than 30mm and do you not have a vacuum cleaner with adjustable suction power? Then we recommend using a nozzle with variable air inlet, for example our Pro-X nozzle. Smaller dust ports will cause excessive vacuum pressure, causing the valve to open continuously.

Do you have questions? Most answers can be found on our FAQ page. Can’t find the answer? Please do not hessitate to contact us via our contact page.